The spring manufacturing process plays an important role in the industry because springs are widely used in many fields, from automobile and machinery manufacturing to household appliances and electronics. To produce a high-quality spring, the process must be carried out strictly and precisely through many elaborate steps.

1: Spring design: The first step is to determine the spring design, including determining the diameter, length, and shape of the spring based on the product requirements. The engineer will analyze the spring’s elastic force and load-bearing capacity to choose the appropriate material.

2: Material selection: Common materials used in spring manufacturing are carbon steel and stainless steel, which have high strength and good elasticity. The material will be cut into sections of suitable length for the design.

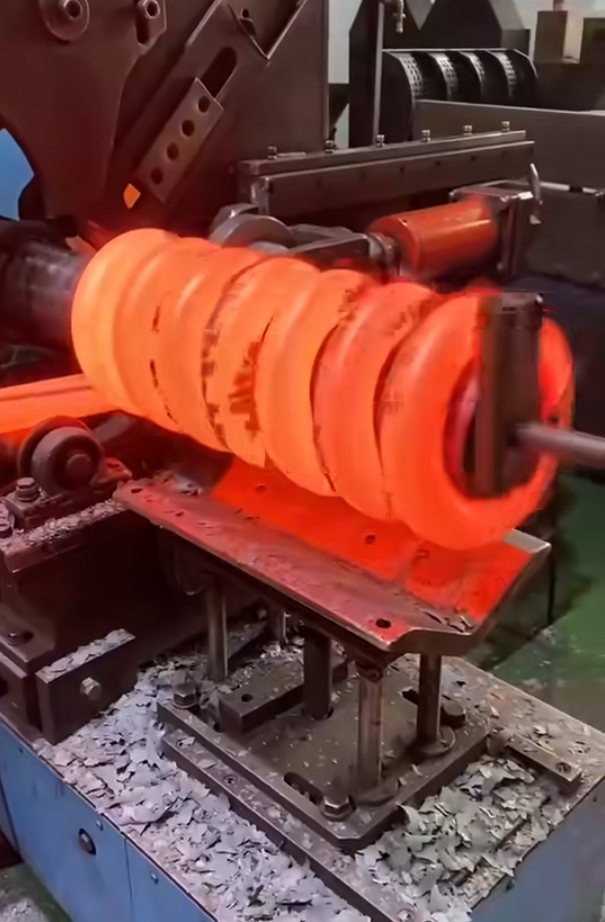

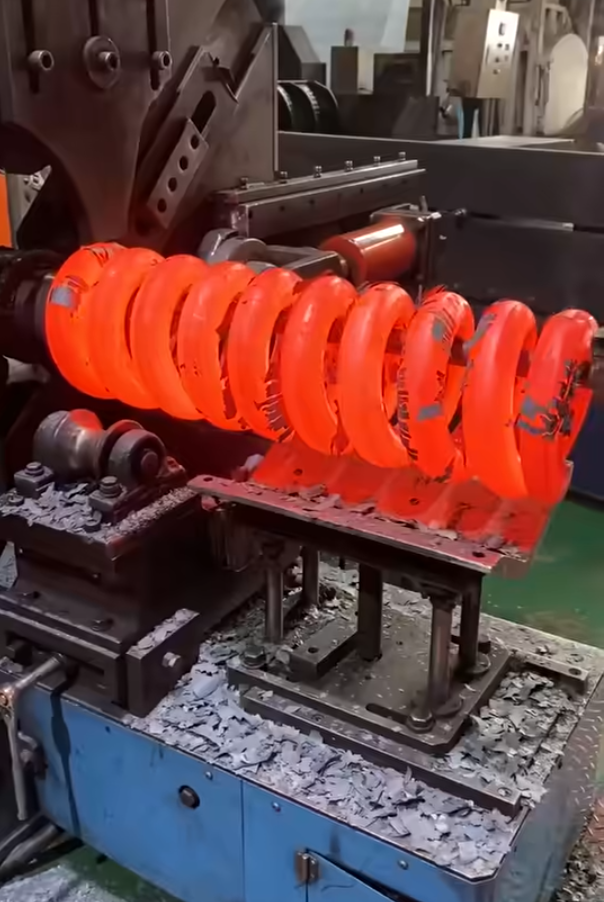

3: Spring bending: The spring is bent into the desired shape using special bending machines. Modern automatic bending machines are capable of adjusting the bending angle and length according to precise specifications, helping to create springs that meet design requirements.

4: Heat treatment: After bending, the spring will undergo heat treatment. High temperatures help release internal stress in the metal, helping the spring maintain its shape and increase its durability.

5: Grinding and finishing: To increase precision and surface finish, the spring will be ground smooth. This helps the spring surface to have no sharp edges, reducing the possibility of wear during use.

6: Surface treatment: The spring can be galvanized or painted to prevent rust, increase durability and aesthetics. This process helps the spring to be used in many different environments without damage.

7: Quality control: Each spring after completion must undergo quality control. Testing criteria include elasticity, bearing capacity, and durability. Any spring that does not meet the requirements will be discarded.

8: Packaging and shipping: Finally, the spring will be packaged according to standards to avoid damage during transportation. The shipment will be transported to the consumer or manufacturer.

The spring production process requires strict and precise control at each stage to ensure high quality products that meet customer requirements. Modern techniques and technology have helped the production process become faster and more efficient, contributing to the development of many industries.